Best Mica Band Heaters and Sensors Distributor in Delhi NCR

Best Mica Band Heaters and Sensors Distributor in Delhi NCR: Fueling Precision Heating Solutions

In industrial usage, reliable and efficient heating systems are needed in order to ensure maximum performance and consistency of the process. Mica Band Heaters , in combination with temperature sensors, offer the ideal combination of heat transfer, ruggedness, and protection, thus making them the preferred choice for different industries. In all types of extrusion, molding, or drying applications, these heaters are engineered to provide high efficiency and enduring performance, hence are a must-have in most industries.

Among the top Delhi NCR suppliers of Mica Band Heaters and temperature sensors, Naman Enterprises stands as a reliable name. It has built a reputation for quality, innovation, and customer satisfaction and provides an extensive array of heating solutions designed to suit various industries.

In this blog, we will discuss the significance of Mica Band Heaters, how sensors improve their performance, and why Naman Enterprises is the first choice to supply high-quality heating products in Delhi NCR. We will also discuss frequently asked questions regarding these products and how they are used.

1. What Are Mica Band Heaters?

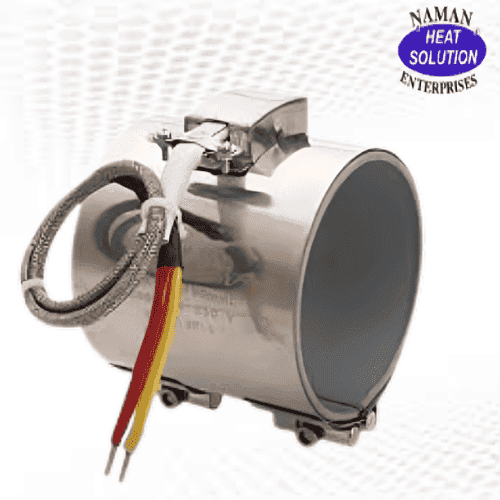

Mica Band Heaters are an electric heating element used extensively for heating cylindrical surfaces like pipes, barrels, or molds. They are highly efficient, durable, and versatile, and are a critical component in most industrial processes.

1.1. Structure and Working Principle

Mica Band Heaters consist of high-quality mica insulation which surrounds a resistance wire wound over an aluminium sheath. With this structure, heat is distributed efficiently, and thermal conductivity is good. The heat is produced when electric current passes through the resistance wire, which in turn is transferred to the object's surface. The mica insulation avoids the loss of heat and distributes the heat evenly throughout the surface.

Mica Band Heaters are frequently utilized to heat machine components across numerous industries, such as plastic molding, food processing, and metal fabrication. They are used in extruders, injection molding machines, and packaging machines, where consistent and accurate heat is essential.

1.2. Why Mica Band Heaters Are Essential in Industrial Heating

- Efficiency: Mica Band Heaters ensure efficient heat transfer, keeping energy expenditure and operating costs low. Their structure ensures minimum heat loss and maximum heating effect, making them an economical choice for most applications.

- Durability: These heaters are engineered to last. Mica is a heat-resistant and insulating material, which provides reliability even in applications under high temperatures.

- Uniform Heating: The uniform heat distribution of Mica Band Heaters is designed to ensure consistent temperatures across the surface, which makes them perfect for applications where temperatures must be uniform.

- Versatility: Mica Band Heaters are highly adaptable and can be developed in various sizes and shapes to suit different industrial needs. They can be easily fitted onto cylindrical surfaces, including pipes, molds, or barrels.

2. How Sensors Complement Mica Band Heaters

Although Mica Band Heaters provide efficient and long-lasting heat, integrating temperature sensors boosts their performance by providing accurate temperature control. The sensors track the heater's temperature and feed back to the control system in real time, making sure the heater remains within the set temperature range.

2.1. Role of Temperature Sensors in Heating Systems

Temperature sensors like thermocouples or RTDs (Resistance Temperature Detectors) operate on the principle of sensing the change in temperature and then converting the same into electrical signals. These electrical signals are passed on to a temperature controller, which regulates the power output of the Mica Band Heater to keep it at a set and precise temperature.

With the inclusion of temperature sensors, companies can realize:

- Accuracy Control: Temperature data from sensors can be used to make precise adjustments to the heater to maintain accuracy.

- Safety: Overheating can be avoided by temperature monitoring through sensors, which prevents equipment damage or safety risks.

- Energy Savings: Energy consumption can be minimized by ensuring that the heater is only on when needed and at the appropriate temperature using sensors.

2.2. Types of Sensors Used with Mica Band Heaters

- Thermocouples: They are the most widely used temperature sensors for Mica Band Heaters. Thermocouples are reasonably priced, durable, and can measure a broad temperature range.

- RTDs (Resistance Temperature Detectors): RTDs are more precise than thermocouples and are better suited for applications that demand pinpoint temperature control. RTDs offer stable outputs across a broader temperature range.

- Thermistors: These sensors find application in low-temperature requirements and are highly accurate with very quick response times.

3. Why Naman Enterprises for Mica Band Heaters and Sensors?

In selecting a supplier of Mica Band Heaters and temperature sensors for Delhi NCR, Naman Enterprises is the name to reckon with. Here are some reasons why companies opt for their products:

3.1. High-Quality Products

Naman Enterprises believes in producing goods of the highest standards in the industry. Their Mica Band Heaters are produced with high-quality materials that provide maximum heat resistance and durable performance. Furthermore, the sensors that they provide are precise and reliable to ensure that your heating system is efficient.

3.2. Customization Options

Naman Enterprises is aware that each business has specific needs. Thus, they provide extensive customization facilities for both Mica Band Heaters and temperature sensors. If you want a particular size, wattage, or voltage heater, or if you want a specific sensor type for your use, Naman Enterprises has the right solution customized to suit your needs.

3.3. Energy Efficiency

Through supplying energy-saving Mica Band Heaters and sensors, Naman Enterprises allows companies to decrease their energy usage and expenses. Their products are optimized to provide excellent heat transfer while reducing energy wastage, resulting in improved overall efficiency.

3.4. On-Time Delivery and Support

Naman Enterprises has a reputation for good customer service and timely delivery. They know how important it is to have a seamless operation, and that is why they make sure to process and deliver orders on time. They also have a support team that can help you choose products, install them, and troubleshoot them, so you can maximize the performance of your heating system.

3.5. Competitive Pricing

Naman Enterprises provides competitive prices for all their products without reducing quality. Their price-effective solutions make them the first choice for companies searching for high-quality Mica Band Heaters and sensors at reduced prices.

4. Uses of Mica Band Heaters and Sensors

Mica Band Heaters and sensors have different uses in various industries. Following are some general industries where they are a necessity:

4.1. Plastic Molding

Mica Band Heaters find extensive application in plastic molding machines for heating molds and barrels. Sensors ensure precise and accurate temperature, avoiding defects in the molded item.

4.2. Packaging Industry

Mica Band Heaters are applied in packaging to heat sealing machines. Sensors provide monitoring of temperature to seal the packing material accurately without over-heating.

4.3. Metalworking and Extrusion

Mica Band Heaters are applied in metalworking operations like extrusion, where they preheat the metal or plastic to the required temperature prior to shaping. Sensors ensure that the process of heating remains accurate, avoiding flaws.

4.4. Food Processing

Mica Band Heaters are applied for heating a number of equipment such as ovens and mixers in food processing. Temperature sensors guarantee that the equipment remains at the appropriate temperature for uniform product quality.

5. FAQs

- What is a Mica Band Heater?

Mica Band Heaters are round heating units utilized to warm surfaces in industrial processes. They consist of mica insulation, which provides effective heat distribution and lower heat loss. - How do temperature sensors function with Mica Band Heaters?

Temperature sensors monitor changes in temperature and send real-time input to a control system. This input allows the Mica Band Heater to work within the intended temperature range, maximizing performance and safety. - Are Mica Band Heaters energy-efficient?

Yes, Mica Band Heaters are engineered to achieve maximum heat transfer and reduce energy loss, and therefore are an energy- Can Mica Band Heaters be customized?

Indeed, Mica Band Heaters may be ordered according to individual size, wattage, and voltage specifications to suit the requirements of many different industrial applications. - Which industries employ Mica Band Heaters?

Mica Band Heaters are employed in plastic molding, packaging, metalworking, and food processing industries where fine and effective heating is necessary.

6. Conclusion

Mica Band Heaters and temperature probes are essential components in a vast majority of industrial heating applications. Their effectiveness, reliability, and versatility make them a first-choice option for companies across a broad range of industries.

Naman Enterprises stands out as a top supplier of Mica Band Heaters and sensors in Delhi NCR, offering high-quality products, customization options, and excellent customer service. Whether you're looking to optimize your heating systems or improve energy efficiency, Naman Enterprises is your trusted partner for all your heating needs.

- Can Mica Band Heaters be customized?